Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

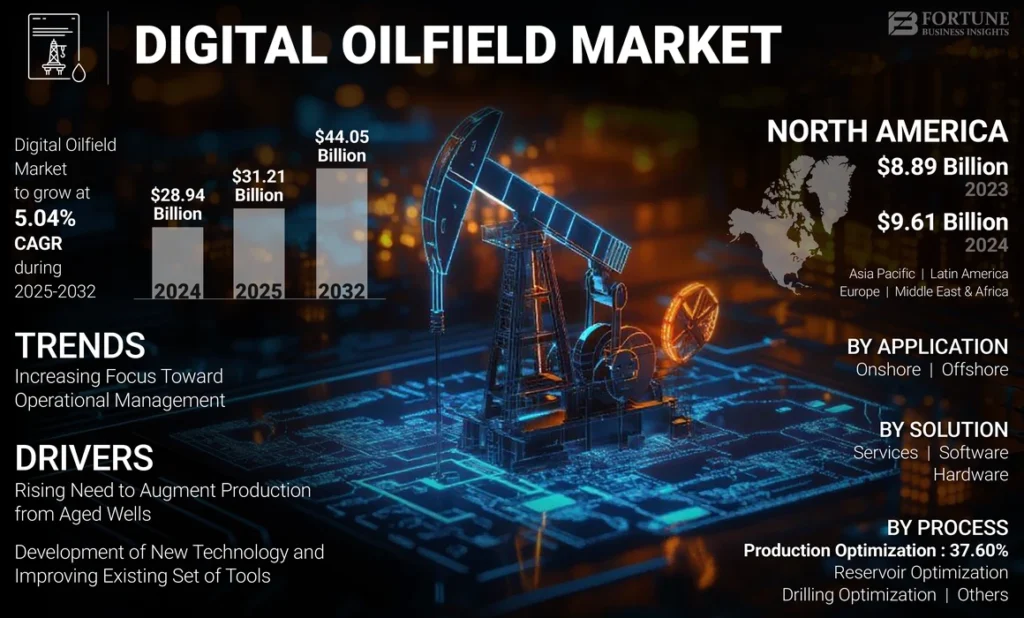

The global energy sector is undergoing a technological transformation unlike anything seen in its century-long history. At the center of this shift is the digital oilfield an integrated ecosystem where artificial intelligence (AI), advanced sensors, automation, and real-time analytics converge to optimize drilling, boost production, and enhance safety.

As operators push into deeper, hotter, and more geologically complex environments, data has become the industry’s most valuable asset. The digital oilfield is no longer a futuristic concept, it is today’s operational reality, reshaping how hydrocarbons are discovered, extracted, and managed.

The digital oilfield refers to the integration of digital technologies across exploration, drilling, production, and asset management. It replaces manual processes with real-time data and automated decision-making at every operational layer.

IoT sensors embedded in wells, rigs, and pipelines

AI-driven analytics for drilling optimization

Digital twins that simulate subsurface conditions

Predictive maintenance systems

Autonomous or semi-autonomous rig operations

Cloud platforms for centralized data management

These technologies allow companies to monitor reservoirs, drilling progress, equipment performance, and safety conditions in real time from anywhere in the world.

Advanced modeling and machine learning tools analyze seismic data, reservoir properties, and drilling parameters to guide drill bits more accurately.

Benefits:

Higher-quality wells

Better reservoir contact

Fewer geological surprises

AI reduces guesswork, enabling drilling teams to make informed decisions faster and with greater accuracy.

Real-time data streams from downhole tools provide continuous updates on:

Pressure

Temperature

Bit rotation

Mud properties

Formation changes

AI platforms analyze this data and recommend optimal parameters, such as weight on bit, mud density, or drilling speed. This reduces non-productive time (NPT) and lowers risks.

Digital oilfields use predictive algorithms to anticipate failures in:

Pumps

Compressors

Rotary systems

Blowout preventers

Instead of reacting to breakdowns, operators replace components just before failure maximizing uptime and preventing costly shutdowns.

A digital twin is a virtual replica of a physical asset, a well, platform, or entire reservoir. These models allow engineers to run simulations for:

Drilling trajectories

Production forecasts

Pressure behavior

Equipment optimization

Digital twins help companies avoid costly trial-and-error methods and reduce drilling risks significantly. They also enable remote collaboration among geologists, drilling engineers, and reservoir teams worldwide.

Automation plays a central role in the digital oilfield, making drilling faster, cleaner, and safer.

Modern rigs increasingly feature automated pipe-handling, casing operations, and even fully automated drill-floor activity.

These systems:

Reduce human error

Prevent accidents

Improve consistency and speed

Robots now perform tasks such as:

Inspecting equipment

Cleaning tanks

Operating in toxic or high-pressure environments

This reduces exposure to hazardous conditions and enhances operational reliability.

The explosion of subsurface data allows operators to better predict how reservoirs evolve over time.

Flow modeling

Fracture analysis in shale wells

Secondary recovery planning

Decline-curve estimates

By understanding reservoir behavior more accurately, companies optimize lift methods and maximize ultimate recovery.

Despite rapid progress, the digital oilfield faces several hurdles:

Oilfields generate enormous amounts of data but much of it is:

Unstructured

Incompatible

Incomplete

Standardizing data across regions and decades is a major challenge.

As operations become more connected, they also become more vulnerable to cyberattacks. Securing pipelines, SCADA systems, and drilling controls is now a top industry priority.

Digital oilfield success requires:

Data scientists

Software engineers

Automation specialists

Many traditional petroleum-focused teams are still adapting to this new paradigm.

Building a digital ecosystem requires major upfront capital. For smaller operators, adoption is slower due to cost constraints.

AI-driven completions optimization has increased productivity in plays such as:

Permian Basin

Eagle Ford

Bakken

U.S. unconventional drillers use analytics to improve fracture designs, manage decline rates, and reduce water usage.

Countries like Saudi Arabia and the UAE have integrated digital twins and AI systems across giant onshore fields, allowing them to maintain high recovery rates while minimizing lifting costs.

Remote monitoring reduces personnel on platforms and improves safety. Automated drill-floor equipment has cut drill times by up to 20%.

The next generation of digital oilfields will be more autonomous, interconnected, and intelligent.

Fully autonomous drilling systems

AI-powered exploration platforms

Advanced robotics for subsea operations

Integrated carbon-management systems

Digital marketplaces for real-time crude trading

As environmental regulations tighten, digital oilfields will also help operators:

Lower emissions

Reduce flaring

Increase efficiency per barrel

Monitor environmental performance

The rise of the digital oilfield marks a turning point in the history of energy production. Data-driven drilling, AI analytics, automation, and digital twins are transforming how companies explore, produce, and manage oil and gas assets. While challenges remain from cybersecurity risks to skill shortages the benefits are undeniable: greater efficiency, enhanced safety, and higher returns on investment.

As global competition intensifies and operational margins shrink, the digital oilfield is not just an innovation, it is becoming the industry’s new operating standard.