Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

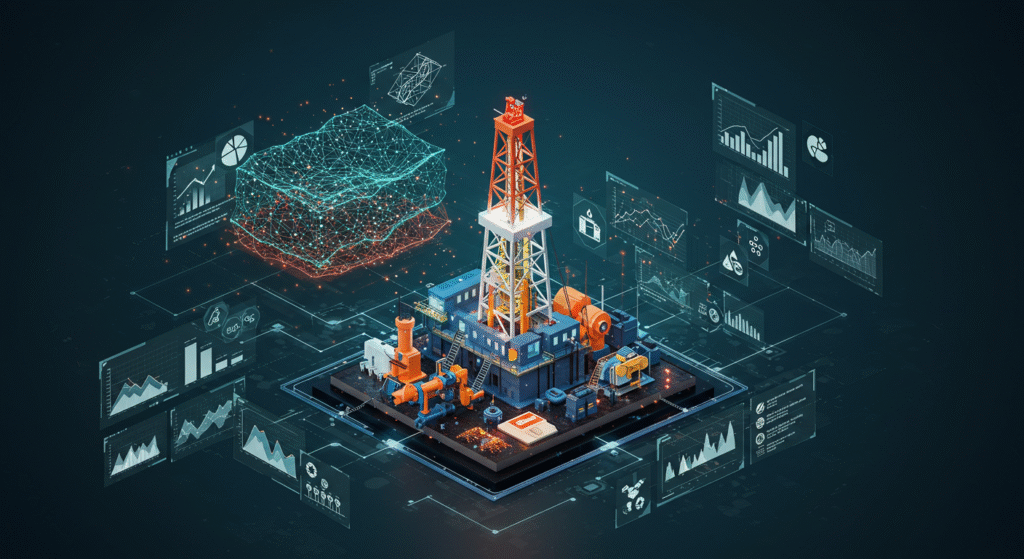

The global energy industry is entering an era where artificial intelligence (AI) is no longer optional, it is essential. Oilfield operations, once defined by heavy machinery and manual processes, are now being reshaped by advanced algorithms, automation, and real-time data analytics.

From drilling optimization to equipment health monitoring and predictive safety, AI is transforming traditional oilfields into smart energy ecosystems. This shift is driving higher efficiency, lowering costs, improving safety, and allowing companies to remain competitive in an increasingly complex market.

As the energy sector navigates volatile prices, rising operational risks, and a growing push for decarbonization, AI stands out as a powerful tool to meet the challenges of tomorrow.

Drilling operations have always required precise calculations and high-risk decision-making. AI now allows companies to analyze millions of data points per second, enabling real-time optimization.

Automated drilling controls adjust weight-on-bit, mud flow, and torque in milliseconds.

Machine-learning algorithms predict drilling hazards before they occur.

Digital well planning reduces non-productive time (NPT) by up to 40%.

AI-driven drilling systems reduce operational costs, minimize downtime, and significantly lower the risk of blowouts or equipment failure.

Traditional maintenance relies on scheduled inspections and reactive repairs. AI introduces predictive maintenance, where algorithms detect anomalies early, often weeks before failure.

Vibration, temperature, and pressure sensors feed data to AI models.

Systems identify patterns linked to pump failures, pipeline corrosion, and valve issues.

Maintenance crews receive alerts with recommended actions.

Reduces unscheduled downtime by 25–35%

Extends equipment life cycles

Avoids catastrophic safety incidents

| Operational Area | Traditional Approach | AI-Driven Approach | Measured Benefit |

|---|---|---|---|

| Drilling Optimization | Manual adjustments | Real-time automation | Up to 20% faster drilling |

| Maintenance | Scheduled/reactive | Predictive analysis | 25–35% fewer breakdowns |

| Reservoir Analysis | Static modeling | Dynamic AI simulations | +15% improved recovery |

| Safety Monitoring | Human reporting | Sensor-based alerts | 40% fewer incidents |

Reservoir characterization and production forecasting have historically been time-consuming and imprecise. AI supercharges this process by integrating seismic, geological, and production data.

Neural networks for enhanced seismic interpretation

Data-driven reservoir simulations predicting flow patterns

Automated decline-curve analysis improving production forecasting

AI’s ability to generate more accurate models leads to higher recovery rates and optimized field development plans.

Safety is one of the most critical aspects of oilfield operations and AI is becoming an indispensable guardian.

Computer vision detects gas leaks, spills, and unsafe worker behavior.

AI-driven drones inspect rigs, tanks, and pipelines without risking personnel.

Environmental monitoring systems track emissions and identify anomalies.

These systems not only enhance worker safety but also help companies stay compliant with environmental regulations.

AI allows companies to track production in real-time and respond instantly to disruptions.

AI adjusts choke settings to optimize flow.

Dynamic optimization models determine ideal injection rates for waterflooding and EOR.

Smart wellheads automatically balance pressure changes.

Result: up to 10–15% production uplift in mature fields.

Digital twins virtual replicas of field assets are becoming central to AI-enhanced operations.

Real-time simulation of equipment behavior

Optimization of field development planning

Risk-free testing of operational scenarios

Remote monitoring and control

Digital twins turn complex field environments into fully interactive digital systems, reducing onsite labor needs and improving decision-making.

Despite its benefits, AI adoption comes with challenges:

Data fragmentation: Legacy systems often operate in silos.

Skill gaps: Engineers must work alongside data scientists.

Cybersecurity risks: Increased connectivity raises attack surface.

Integration complexity: Requires standardized workflows and infrastructure.

Companies that invest in integration, training, and data management frameworks will gain the most value.

The next decade will usher in autonomous oilfield operations, with minimal human intervention.

Autonomous drilling rigs

AI-managed subsea production

Fully automated inspection via robotics and drones

AI trading platforms integrated with real-time production data

As AI continues to mature, oilfields will evolve into intelligent, self-adjusting systems capable of operating with unprecedented safety and efficiency.

AI is fundamentally transforming oilfield operations, making them smarter, safer, and more efficient. From drilling automation to predictive maintenance and real-time safety monitoring, AI is reshaping how hydrocarbons are produced in an era of rising energy demand and tightening environmental expectations.

The companies that embrace AI now will lead the next generation of energy production, gaining a decisive advantage in cost, productivity, and sustainability.

In the race to modernize global energy systems, AI is not just an enhancement, it is the central engine powering the oilfield of the future.