Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

The offshore oil and gas industry has always been one of the most challenging environments for technology. Harsh weather, deep waters, and high costs make exploration and production in offshore fields a complex undertaking. In recent decades, however, a powerful ally has emerged to transform offshore operations: robotics.

From remotely operated vehicles (ROVs) to autonomous drones, robotics is reshaping how offshore companies approach safety, efficiency, and sustainability.

Offshore environments present unique challenges: Depth: Many offshore fields lie thousands of meters beneath the surface. Safety Risks: Human divers face extreme hazards during inspections or repairs. High Costs: Offshore drilling and maintenance are capital-intensive. Robotics offers solutions to these problems by enabling automation, precision, and remote operation.

Cost Efficiency: Robots lower operational costs by reducing downtime and minimizing the need for large crews.

Precision: Advanced sensors enable highly accurate measurements and interventions.

Safety: Robotics keeps human workers out of dangerous environments.

Sustainability: Real-time monitoring helps companies meet environmental standards.

Despite the benefits, several challenges remain:

High Upfront Costs: Advanced robotic systems require significant capital investment.

Technical Complexity: Offshore robotics requires specialized operators and maintenance.

Cybersecurity: Increased automation introduces vulnerability to cyberattacks.

Regulatory Barriers: Rules governing offshore robotics are still evolving.

Equinor (Norway) has tested subsea drones for autonomous inspections, aiming to reduce the number of offshore personnel.

BP uses drones to inspect flare stacks, cutting inspection times by up to 90% (BP).

TotalEnergies has deployed robotic arms for underwater valve operations, improving response times.

These examples highlight how major energy players are investing in robotics for safer, smarter operations.

Robotics is not only transforming traditional oil and gas but also bridging into renewables:

Offshore wind farms rely on ROVs for cable laying and maintenance.

Drones monitor turbine blades and offshore platforms.

Robotics reduces the carbon footprint of offshore operations through efficiency gains.

As oil companies diversify into renewables, robotics will play a dual role in hydrocarbons and clean energy.

Emerging trends include:

AI-Powered Autonomy: Robots will make more decisions without human intervention.

Swarm Robotics: Multiple AUVs and drones working together for complex tasks.

Digital Twins: Robots feeding real-time data into virtual models of offshore assets.

Hybrid Energy Operations: Robots that support both oil rigs and offshore wind platforms.

According to Deloitte, digital and robotic solutions could reduce offshore operational costs by up to 20–25% over the next decade.

Robotics is no longer science fiction in offshore oil and gas, it is a reality transforming exploration, production, and maintenance.

By enhancing safety, reducing costs, and enabling environmental monitoring, robotics ensures that offshore operations remain viable in an era of rising complexity and energy transition.

For companies navigating the future of offshore oil and gas, robotics is not an option, it is a necessity.

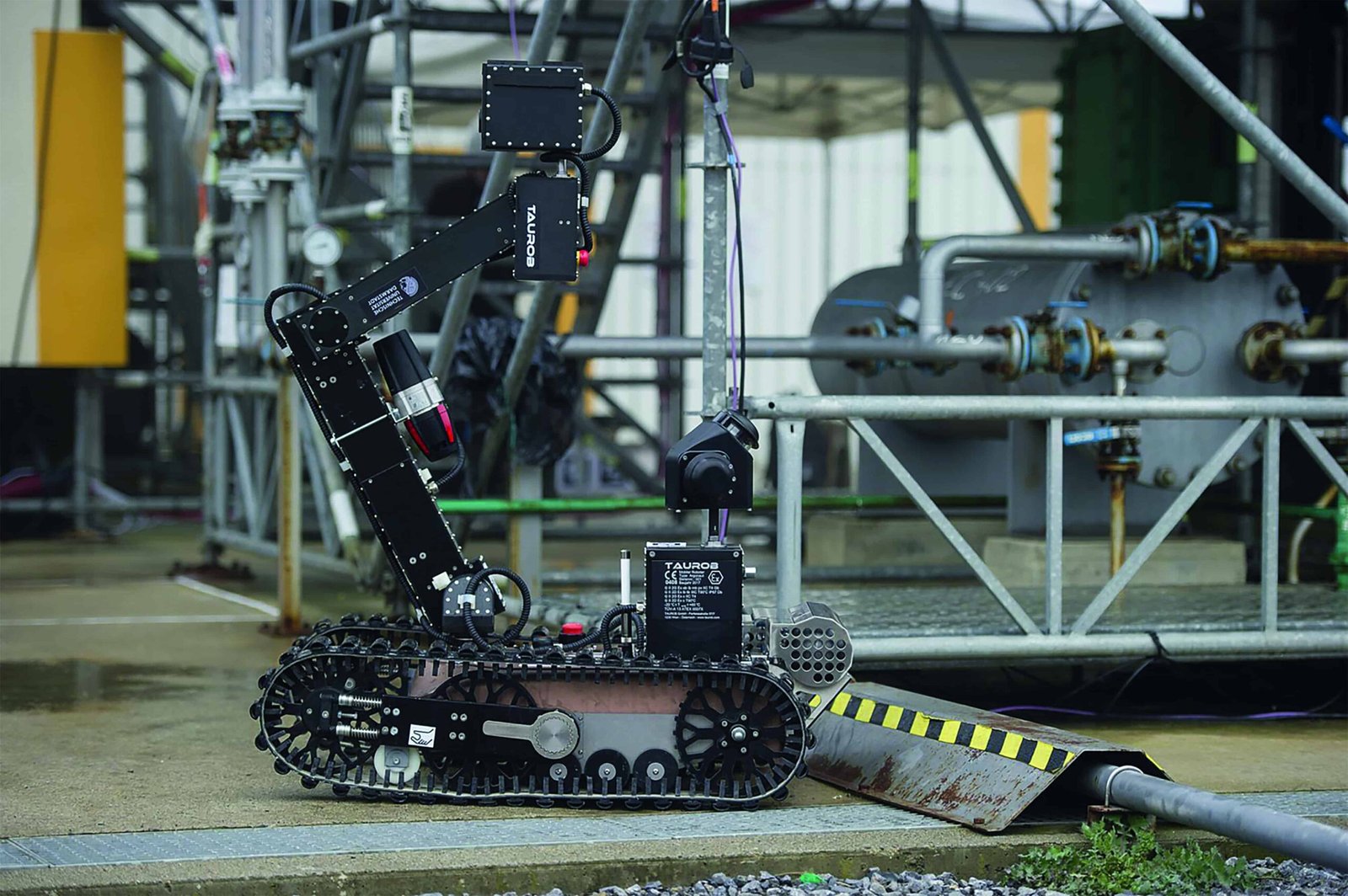

ROVs are tethered, highly maneuverable underwater robots used for tasks such as:

Pipeline inspections

Valve operations

Deep-sea construction support

Companies like Saab Seaeye and Oceaneering International lead in ROV technology (Oceaneering).

Unlike ROVs, AUVs operate untethered, making them ideal for:

Seabed mapping

Environmental monitoring

Pre-drilling surveys

AUVs are being developed for greater autonomy, reducing the need for human oversight.

Aerial drones are increasingly used for:

Offshore rig inspections

Flare stack monitoring

Security patrols

These drones reduce the need for helicopters and improve worker safety (Shell).

Companies like National Oilwell Varco (NOV) are deploying automated drilling rigs that use robotics to:

Improve drilling precision

Reduce human error

Increase efficiency in repetitive tasks

Robots equipped with cameras and sensors inspect subsea pipelines and risers.

Robotic crawlers detect corrosion, leaks, and cracks.

This reduces downtime and prevents accidents.

ROVs and robotic arms handle tasks like connecting subsea cables or operating valves, jobs once requiring costly diver interventions.

By replacing human divers with robots, offshore firms reduce exposure to extreme risks such as high pressure, deep water, and toxic leaks.

Robots track marine biodiversity and monitor oil spills. AI-equipped AUVs can predict spill trajectories, supporting rapid response efforts.

Europe’s diversification is not just about LNG new pipeline corridors are changing the map of energy flows.

Southern Gas Corridor: Delivers Caspian gas from Azerbaijan via the Trans Adriatic Pipeline (TAP) into Italy (TAP AG).

Norwegian Pipelines: Norway increased exports to Europe, becoming its top pipeline supplier in 2023 (Norwegian Petroleum Directorate).

Baltic Pipe: Connects Norwegian gas fields with Poland, reducing reliance on Russia (Baltic Pipe Project).

EastMed Pipeline (planned): A proposed route to bring gas from Israel and Cyprus to Europe.

These projects reflect Europe’s determination to spread risk across multiple suppliers.